By Percy Sanford, AAM Leader

Urban air mobility (AAM) represents the next level of personal urban transport. As large cities grow increasingly crowded, the mobility of their citizens decreases dramatically. This is evident in cities like New York, Los Angeles, and San Francisco, where daily commutes are measured in hours rather than minutes. But the industry must solve the challenge of batteries for urban air mobility before large-scale adoption is possible.

AAM intends to address this problem by moving urban transportation from two dimensions to three. Flying vehicles, like those seen in Star Wars or The Jetsons, can reduce congestion significantly by allowing multiple flows of traffic to pass over the same physical road.

However, AAM faces technological challenges. The development of AAM vehicles, or vertical takeoff and landing (VTOL) aircraft, has proven to be challenging. And one of the biggest challenges in making AAM feasible is batteries.

Why AAM Needs Batteries

Traditional means of air transportation cannot be used for urban air mobility. The helicopter is too loud and airplanes require a runway for takeoff and landing. In an urban environment, neither of these is a workable solution.

As a result, VTOL manufacturers are exploring hybrid and electric options. In terms of eVTOL (electric VTOL), these types of vehicles are much quieter to run and make it feasible to create and power a vehicle that can perform the vertical takeoffs and landings needed for AAM.

However, electric vehicles need power, and this power comes from batteries. While the state of the art in batteries has advanced significantly in recent years, building a battery capable of meeting the needs of AAM poses a significant challenge.

The Battery Development Challenge

Uber has been leading the charge for battery development for AAMs. They have published a document outlining the requirements that a AAM vehicle must fulfill. Some of these requirements are for the batteries in these vehicles:

- Reserves: The battery should always have reserve power for

- A balked landing

- A 6-mile diversion at 500 feet above ground level

- A successful landing

- Distance: Ability to power the vehicle for 60 miles of flight while maintaining sufficient reserves

- The measurement should be completed at the battery’s end of life

- Repeatability: Ability to fly for 3 hours, 25 miles at a time with 7-minute recharging stops

Uber hopes to have vehicles capable of meeting these requirements available and affordable by 2023. In a presentation on March 27, 2018, Uber admitted that batteries capable of meeting these requirements simply do not exist and requested aid from the battery-expert community to meet these goals.

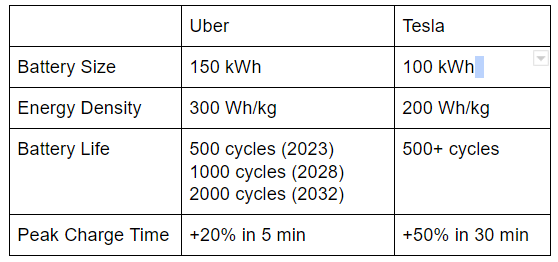

However, the challenge is significant. The table below compares the battery that Uber needs with the one from the 2017 Tesla S 100D (one of the best electric vehicles on the market).

While the differences between Uber’s requirements and Tesla’s reality may seem slight, they’re complicated by the fact that the modern lithium-ion battery is nearly as good as it can get. Achieving Uber’s targets will likely require the development of a battery with a whole new chemical makeup, which can take as long as 15 years.

Meeting the Challenge of Batteries for Advanced Air Mobility

While the development of batteries that can fuel its proposed AAM vehicles is a challenge, Uber seems ready and willing to meet it. At the second Uber Elevate Summit, Uber announced a partnership with E-One Moli Energy to develop batteries to power its vehicles. E-One Moli is a known player in the space of lithium-ion batteries, and Uber intends to use their technology to design the batteries necessary to make AAM a reality.

The challenges faced by AAM are large, but when innovative companies come together great things happen. Performance brings 20+ years of safety-critical systems and software development and extensive airworthiness validation experience to AAM. If you are an AAM innovator and want to know how Performance can help you, contact Performance Software today.